Choose the Right Wire for 100 Amp Sub Panel

Sub panel wire sizing has gotten complicated with all the AWG numbers, material choices, and voltage drop calculations flying around. As someone who has installed sub panels in every configuration, I learned everything there is to know about getting wire sizing right. Today, I will share it all with you.

Why Wire Size Matters

Probably should have led with this section, honestly—incorrect wire size leads to overheating, fire hazards, and power loss.

Recommended Wire Sizes

That’s what makes wire selection endearing to us safety-minded electricians—the right choice prevents problems:

- Copper: 1 AWG for typical runs

- Aluminum: 3/0 AWG (aluminum requires larger gauge due to lower conductivity)

Copper vs. Aluminum

- Copper: Higher conductivity, more stable, less expansion/contraction, safer—but more expensive

- Aluminum: Less expensive, lighter, but expands more with temperature changes. Requires special connectors and careful installation

Voltage Drop Considerations

For runs over 100 feet, upsize wire to keep voltage drop under 3%:

- Long runs with copper: Use 1/0 or 2/0 AWG

- Long runs with aluminum: Use 4/0 AWG

NEC Requirements

The National Electrical Code provides guidelines. Always check local codes, which may have additional requirements beyond NEC standards.

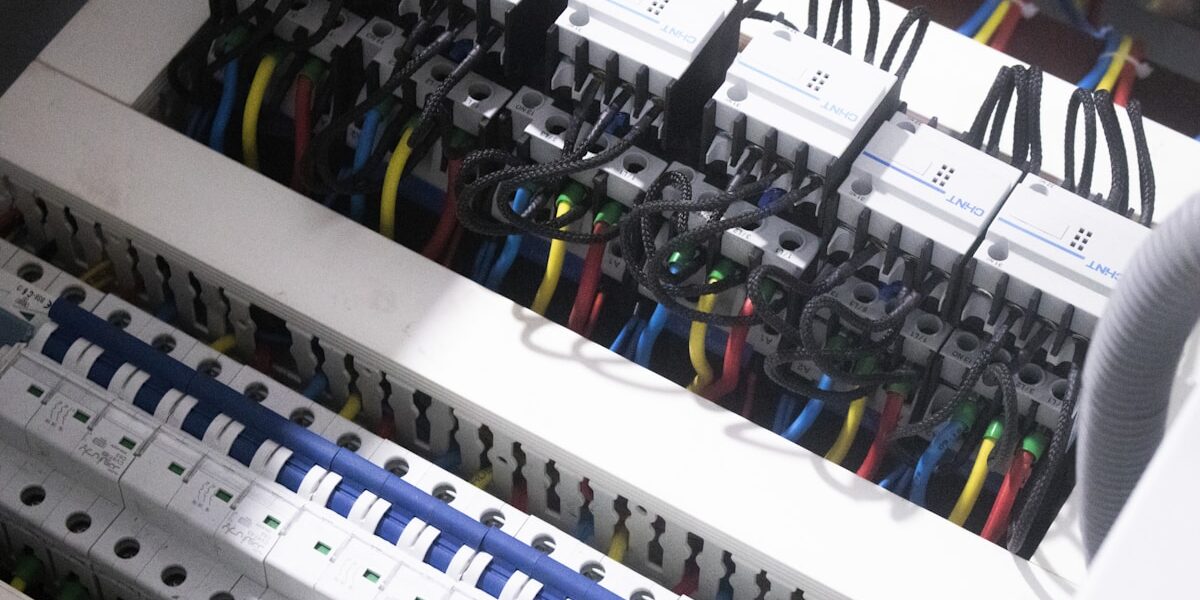

Installation Basics

- Turn off main power before starting

- Mount sub panel at chosen location

- Run appropriately sized wire

- Connect ground and neutral to bus bars

- Install breakers and connect hot wires

- Test all connections before turning power on

Maintenance

Check connections periodically, especially with aluminum wiring. Look for signs of corrosion or overheating. Tighten loose connections and replace damaged wires immediately.